|

Design

|

Our design team plays a vital roll in ensuring a project is executed flawlessly.

We use the latest version of Solidworks on all our projects. Solidworks allows our customers to see exactly what they are getting before we cut metal. The lines of communication are kept open, and everybody knows the project scope and details moving forward. The use of exploded views, cut-aways, and even animation is used during the design approval stage. After the design approval proper drawings are generated and routed through the shop. Project drawings are archived on our server and available upon request.

|

|

Our design team routinely work on:

|

- Complex machine assemblies

- Part Stress Analysis

- Fixturing design based on customers 2D or 3D data.

- We accept all forms of Cad data. (dwg, dxf, iges, stp, etc.)

- Assembly animation and interference check

- Plastic part creation for Plastic Injection Mold Industry

|

|

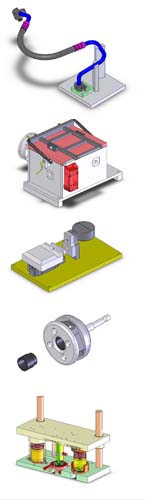

Braze Fixture designed

from customer .step file |

|

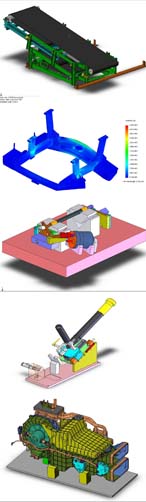

Retractable conveyor

design |

| Stainless vacuum

chamber for quality

assurance |

Report done to determine

strength of material transfer

cart with section removed. |

| Depth Gauge using

Mitutoyo digital mic |

Hose crimp fixture designed

to locate part during crimping |

| Custom designed

torque socket for

shipping cap |

Torque fixture designed

to torque screw to spec.

Part locked in fixture until

torque specification is met. |

| Assembly die set |

Assembly fixture designed

around customer's .step file |

|

|